Products

- Printed rollstock

- High-barrier flexible packaging

- Matte/gloss flexible packaging

- Compostable flexible packaging

- Recyclable flexible packaging

- Stick pack film laminations

- Lidding films

- Peel and reseal rollstock

- Shrink bands

- HFFS and VFFS rollstock

- Inno-Lok® pre-zippered rollstock

- Laser die-cut window rollstock

- Paper flexible packaging

- High burst strength flexible packaging

- Child-resistant flexible packaging

- Premade pouches

- Roll-fed labels

- Shrink sleeves

- Stretch sleeves

- Cold-seal packaging

- Thermoformed food trays

- Functional bags & pouches

Laser die-cut window rollstock

One of the most important packaging features for consumers today is the ability to see the product inside the packaging. Our patented laser die-cut rollstock (DCRS) technology gives your consumers this important feature without sacrificing efficiency or shelf life.

This proprietary technology allows us to use high-speed lasers to die-cut customized windows into paper flexible packaging laminations in roll form. Compared to equivalent forms of packaging such as stand-up weber bags, die-cut rollstock provides several benefits:

- Adds significant shelf life for your product with better barrier and the ability to be gas flushable.

- Large productivity improvements and production savings due to automated packing and increased output per hour.

- Less inventory space required because die-cut rollstock takes 20% less storage space than bulky premade bags prior to packing.

- Prevents infestation; pests can’t enter bag because it is heat sealed.

- Low cost machining changeover; existing automated vertical FFS packaging machines can be modified to fill die-cut window rollstock.

Applications for die-cut window rollstock (DCRS)

Die-cut window rollstock is ideal for many applications, such as:

- Snacks

- Bakery products

- Deli products

- Pet treats

- Grains & cereals

- Dried meats & fruits

- Confectionery products

Patented die-cutting solutions

- State-of-the-art die-cutting technology

- Patented inline die-cutting process using extrusion lamination

- Heat-sealable liner & hermetic seals to increase shelf life

- Rollstock can run on VFFS and HFFS equipment

Cost savings and brand improvement with DCRS

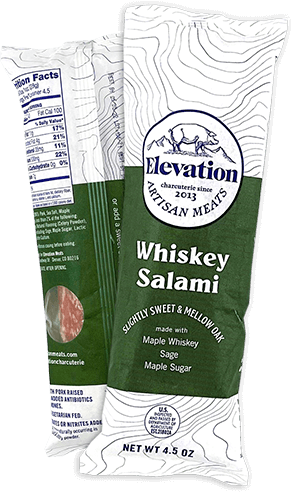

C-P’s DCRS looks great and saves time by providing an automated packing solution for products such as cured meats.

After switching from hand-wrapped packaging to C-P Flexible Packaging’s die-cut window rollstock (DCRS) utilizing a flow wrapper, Elevation Meats saw improved productivity efficiency, cost savings, and brand image.

After switching from hand-wrapped packaging to C-P Flexible Packaging’s die-cut window rollstock (DCRS) utilizing a flow wrapper, Elevation Meats saw improved productivity efficiency, cost savings, and brand image.

Let's talk flexible packaging.

Ask us your packaging questions, and we’ll see how we can help you overcome your next packaging challenge.

Sustainable Packaging

Learn more about our sustainable packaging options including: recyclable, PCR, compostable, and biopolymer usage

GreenStream Products