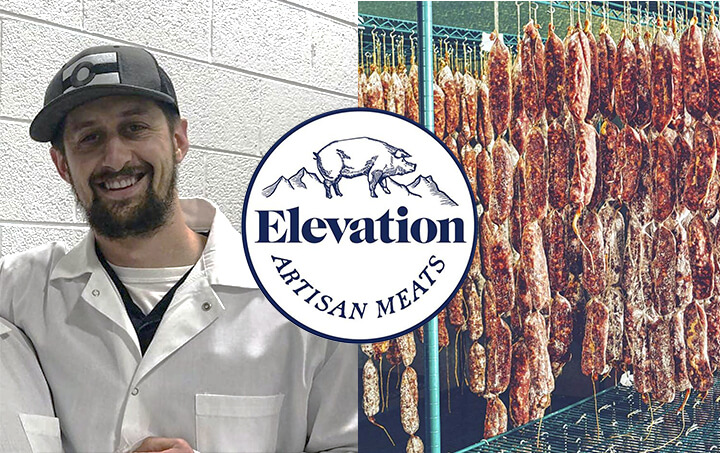

Meet Elevation Artisan Meats

We recently sat down with Chad Nelan, Owner of Elevation Artisan Meats (Elevation Meats or Elevation Charcuterie). Chad started out his career as a butcher and used that experience to open Elevation Meats, specializing in charcuterie and salami.

Based out of Denver, CO, the company prides itself on sourcing the highest quality ingredients and staying ahead of best practices. Elevation continues to champion the “old” artisan way of creating their products while adhering to the stringent rules of the USDA.

The problem with hand-wrapped packaging

Elevation Meats started out by packaging their meat products by hand rolling them in paper and applying a label. This process would take roughly four minutes per package.

The company had a staff of ~50-60 people hand-rolling salamis at one time to help speed up the process. Nelan mentioned it looked like the original Willy Wonka and the Chocolate Factory movie scene where hundreds of people are seen ripping open candy bars to find the golden ticket. The process wasn’t efficient as it took time and required a lot of workers.

Another issue of having hand-rolled packaging for artisan meats was not having the option for a window. Consumers couldn’t see the product inside the packaging.

How die-cut rollstock improved productivity and branding

Looking for a more efficient way to package their meats, Chad met with C-P Flexible Packaging. He learned about our patented laser die-cut window rollstock technology

(DCRS) and how it could transform his production efficiency and add a window to his packaging. Chad worked with his copacker to utilize a flow-wrapping machine that worked seamlessly with our DCRS material.

After the switch, Elevation Meats saw a significant increase in productivity. With only a couple people operating the machinery, they can produce packaging 8x faster than before. This efficiency change has cut their packaging costs in half.

Before (hand-wrapped)

- 60 workers needed to produce packaging

- 4 packages/minute

- Packaging costs: $0.29/unit

- Extra label needed

- No window

After (flow wrap – DCRS)

- 2 workers needed to produce packaging

- 32 packages/minute

- Packaging costs: $0.14/unit

- Clean, professional look and feel

- Features a window to show product

Chad admitted he was a bit nervous about consumer reactions to the new packaging. Initial feedback has been positive; his customers love the updated look. The DCRS packaging looks clean and professional, shows the product through a circular die-cut window, and displays great on store shelves.

Watch the full interview

Check out our interview with Chad in The Switch from Hand-wrapped Packaging to Die-cut Window Rollstock for Artisan Meats: