Perhaps the simplest way to introduce cold-seal packaging is by comparing it to its old-guard counterpart: Heat-seal packaging.

They’re similar in many ways. Both types of flexible packaging come in rolls, which are run on your horizontal form/fill/seal (HFFS) packaging line to form bar wraps for candy, granola bars, and other high-end snacks.

The difference lies in the adhesive properties. Heat-seal adhesives require that three parameters (heat, pressure, and dwell time) be in perfect harmony to achieve a secure package seal. Cold-seal adhesives rely on just one parameter — pressure.

This may seem like a small difference, but it’s far from inconsequential. Eliminating heat and dwell time helps co-packers cut energy costs, boost packaging speeds, and reduce product spoilage due to packaging burn. All huge wins for co-packers and brands alike.

What, exactly, is cold-seal packaging?

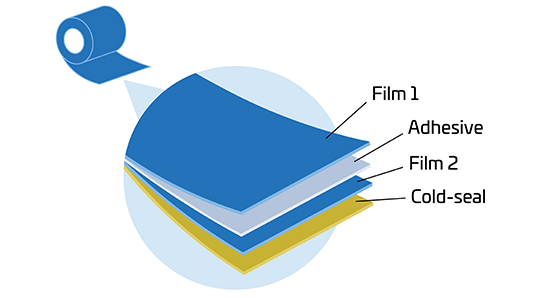

Cold-seal packaging is a type of printed rollstock designed to be run on HFFS equipment to form bar wraps. It’s often a two-film lamination, with pattern-applied adhesive on the inside surface of the web in a pattern registered/aligned with the graphics on the outside of the web.

Benefits of cold-seal packaging for co-packers

Up to 10x increase in packaging speed

This is the principal benefit of cold-seal packaging. Even doubling the packaging speed increases the co-packer’s capacity and eliminates the immediate need for a new packaging line, a costly capital expenditure.

Eliminates heat from the process

Remember, heat-seal adhesives require a very careful balance of temperature, time, and pressure to form a seal. If that balance is not met, the package won’t seal, the package can burn, and the product can get damaged.

Because there’s only one parameter to consider, cold-seal packages make adjustments much simpler. And that’s just one benefit of eliminating heat from the process.

Eliminating heat also:

- Reduces startup time — you no longer have to wait for the packaging line to heat up

- Means heat-sensitive products won’t get damaged if the packaging line stops

- Eliminates package distortions and product spoilage due to heat

- Reduces your energy costs, as you don’t have to waste energy maintaining temperature nor worry about unreliable heaters or thermocouplers

- Makes your facility safer by eliminating operator injuries due to burns

Runs on your existing heat-seal packaging line

Just turn off the heat. From there you can test the limits of your packaging line’s speed specifications.

Historically, it’s been hard to source cold-seal packaging for smaller brands

Cold seal isn’t new — large brands have been running it for decades, reaping all of the benefits listed above.

But until now, it’s been largely out of reach for the small-to-midsized brands that make up a healthy percentage of co-packing clients. To put it into perspective, there are more than 400 flexible packaging converters, and almost none of them have tackled short-run cold-seal packaging for midsized brands.

Why? It really boils down to three things: Expertise, the currently installed asset base, and economics.

Cold seal, for all its benefits, is a nature-based product and can be unstable if handled improperly. Manufacturing cold-seal packaging so that it runs seamlessly on your packaging line requires the highest level of technical and application-specific expertise.

Few converters were willing — or even able — to throw their hat in the cold-seal ring. Those that did focused on long runs for big brands.

Their lines are set up to print, laminate, and apply cold seal in a single pass at speeds as fast as 12,000 feet per minute. At that rate, you could easily finish 100,000 bar wraps in less than a minute.

Sounds great in theory, but the cost of setting up this large in-line process is significant, and it’s the same whether you want 100,000 or 100 million impressions.

Additionally, any quality challenge that might occur makes its way through all phases of the cold-seal film production This is a huge liability for converters, so most spread the risk out over exceedingly long runs and simply won’t do short-run production.

Why the “long-run-only” mindset doesn’t work in today’s SKU-proliferated market

As you well know, the “long-run-only” mindset is hardly isolated to cold-seal packaging products — it permeates all areas of flexible packaging.

The current installed asset base at cold-seal convertors drives the need for longer runs. This means big brands move to the top of the priority list, while converters attempt to standardize packaging across several smaller clients in an effort to lengthen production runs.

For small and midsized brands, this means their packaging is often improperly sized, overly engineered, or scheduled at inconvenient intervals: They have to wait for the next long run to receive their packaging order.

This mindset often precludes midsized brands and the co-packers who serve them from accessing specialty packaging technologies like cold seal.

But the market has changed. With the growth of healthy snacking, focus on portion control, and overall increased variety, the number of SKUs has exploded.

It’s not just midsized brands that need short runs anymore — even the snacking behemoths are requiring shorter and shorter runs. Take Oreo, for instance. There used to be just the original chocolate wafers, and now there are 25 different flavors, packaged 75 different ways. And more package variation means smaller production runs.

To serve the short-run needs of small and large brands alike, a new “client-first” mindset is needed.

How we made cold seal accessible (and affordable) for co-packers serving smaller brands

As we mentioned before, there are two primary reasons other converters don’t offer short-run cold-seal packaging: Expertise, the currently installed asset base, and economics.

We’ve addressed each head-on, empowering us to partner with co-packers to bring cold-seal technology to small and midsized brands.

Three decades of cold-seal expertise at the helm

We spoke with brands and contract manufacturers to identify what they need out of cold-seal packaging solutions. We listened, and invested in the production assets and service programs that address their primary concerns:

- Fit-for-use cold-seal packaging films customized to their individual products requirements

- Order quantities that are aligned with your production requirements

- Inventory management programs that provide manageable lead times and minimize working capital extension of cold-seal film inventories

- Reduced risk of obsolescence, as we have lower minimum order requirements than other suppliers

- On-site field technical service to ensure continual efficient production and proactive identification of future cost saving opportunities

- Cold-seal films, as part of a broad product line of barrier and non-barrier printed rollstock, Inno-Lok® rollstock film, premade pouches, shrink sleeves, roll fed, and stretch labels

Our goal is to maximize the value of our partnership. We welcome discussions concerning how we mold our cold-seal packaging solutions around your brand’s particular needs.

Turning the economics on their head

While continuous, high-speed, one-pass production is great for long runs, it presents too much risk for short runs.

So we split up the process.

There’s a certain amount of waste it takes to fine-tune each step in the process to a particular package. By breaking out each step (printing, laminating, applying cold seal, slitting, rewinding) we’re able to reduce the amount of startup waste for each one of those processes and, ultimately, reduce the cost and risk involved with producing short runs.

With our process, it makes economic sense to produce shorter runs — finally opening up an opportunity for smaller brands to capitalize on the benefits of cold-seal technology.

For your midsized clients that think the long-term benefits of switching technologies outweigh the upfront and incremental cost increase, we’re well-equipped to meet their technical support and run size needs.

For co-packers, the switch to cold seal is an economic no-brainer.

Granted, cold-seal packaging is more expensive per impression than its heat-seal counterpart. But the increased throughput per hour with cold-seal packaging more than offsets the higher cost per impression, resulting in better margins on your product. Of course, this is dependent on the ability of your cold-seal film supplier to supply the order quantities you need within your desired timeframe.

Get your guide to cold-seal packaging

Short runs of cold-seal packaging are now possible, and the potential for this technology to differentiate co-packers to the midsized clients they serve is too great to ignore.

We created a guide for co-packers that are either considering adding cold seal to their product portfolio by establishing a strategic partnership with a cold-seal packaging supplier, or those that are having trouble with their current supplier. Download your copy today.

Guide to cold-seal packaging for co-packers

Learn what cold seal is and how to vet potential suppliers.